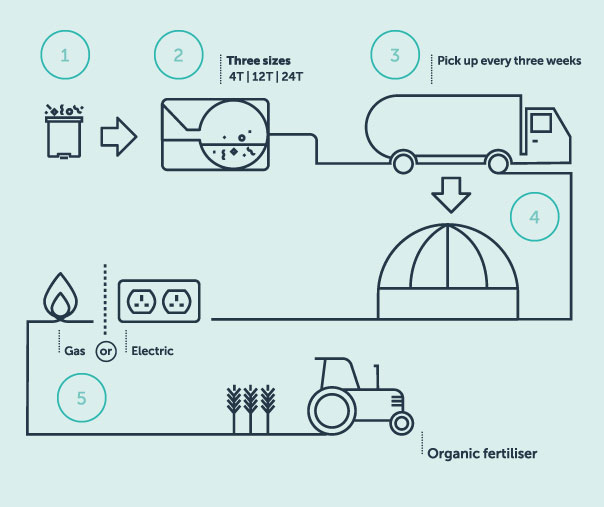

Our Solution

1

Food waste is tipped into the unit2

Waste is ground up and held under vacuum3

Tank level is remotely monitored; automatic dispatch when tank is full4

Waste is delivered to anaerobic digestion plant5

Waste is converted into energy and organic fertiliser

Consultation phase

During the consultation phase we will offer to arrange a demonstration so you can see how the OWL system works firsthand.

A comprehensive site survey will be developed with you to identify all your operational and installation needs.

We will:

1

Analyse your current waste practices to quantify your potential savings.2

Determine the appropriate size and location for the BioWhale and confirm suitability.3

Assess your operational needs, including the number and size of food waste receptacles required and the appropriate process for separating your food waste. In addition, OWL will evaluate whether options such as a bin-lifter or satellite disposal chute are desirable.4

Discuss the logistics for pick-ups, including timings and site access.5

Discuss a training plan for your workers and determine who will require training.6

Review our standard contract and discuss pricing, terms and conditions.

Implementation phase

The implementation phase is comprised of Installation of the equipment and training of staff.

Installation at your location can be completed in less than a day, with no disruption to your work activities.

Training will be tailored to the needs of your staff.

OWL’s training programme includes:

1

Training materials and user manuals (written and web based).2

On-site staff training on how to use the BioWhale and how to segregate food waste effectively.3

The OWL team will work with you to design a customised report that will support your green certification activities.

Ongoing Maintenance & Support

OWL's solution includes bi-annual maintenance and service along with 24/7 hotline support for unplanned repairs or customer emergencies, such as loss of electricity. We will work with you to schedule your twice annual servicing at a time convenient to your business.

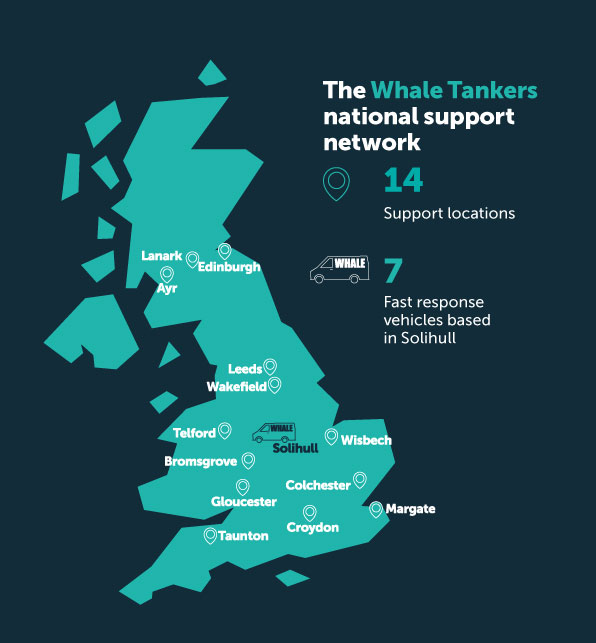

OWL's outstanding maintenance and service programme is delivered together with our partners, Whale Tankers, (the BioWhale’s manufacturer), and is backed by 14 satellite Service Centres across the UK.

BioWhale

The BioWhale was designed specifically for OWL by Whale Tankers, the UK’s leading waste tanker manufacturing company, with a reputation for quality, value and reliability. Based in Solihull since 1969, Whale maintains a continuous commitment to product improvement and environmentally sound manufacturing processes.

Read below for a basic description of the BioWhale. Full specifications and details are available here.

1

How it works

Once food waste is tipped into the stainless steel hopper, a button activates a vacuum to suck the food waste into the unit. The vacuum action shreds the waste into small pieces and delivers it to a macerator that grinds it even smaller. The ground waste is then held under an air vacuum to ensure there is no odour released and the food waste does not lose any of its energy value.

The tank is slowly mixed to begin breaking down the food waste into simple sugars (glucose), fatty acids and amino acids. The storage tank level is monitored online and when it approaches capacity, an OWL vacuum tanker truck is automatically dispatched to empty the tank.

2

Ease of use

The BioWhale is designed for safe and easy use, meeting all UK regulations and standards. The unit comes installed in a steel container; locked steel panel doors protect the hopper and controls. The BioWhale plugs into the standard 440 volt/32 amp electrical service and uses very little electricity. The BioWhale unit uses no water and so does not need a connection to your clean water or wastewater services.

While only food waste should to be fed into the hopper, the BioWhale can manage the occasional mistake, as it routes non-food waste to a sump, where articles such as cutlery, can be removed during the twice yearly routine service call.

3

�Reliability

The BioWhale is a robust, industrial piece of equipment using well-tested components. The tanks and control system are manufactured in the UK at BioWhale’s ISO 9001 facility that has built over 4,000 tank systems.

The BioWhale is monitored online with a sophisticated diagnostic system, which tracks multiple performance points. Any deviations from standards are automatically alerted to OWL control centre that can dispatch a fully equipped service vehicle from one of 14 national services centres.

4

�Unit dimensions

Compact BioWhale

Installed in 10-foot long container

Dimensions

length

width

height

3.05m

2.4m

2.59m

(equivalent to space for 4-6 wheeled waste bins)

Tank capacity: 4,000 litres (equivalent to 4 tonnes food waste)

Standard BioWhale

Installed in 20-foot long container

Dimensions

length

width

height

6.1m

2.4m

2.59m

(equivalent to space for 8-10 wheeled waste bins)

Tank capacity: 12,000 litres (equivalent to 12 tonnes food waste)

Large BioWhale

Installed in 40-foot long container

Dimensions

length

width

height

12.2m

2.4m

2.59m

(equivalent to space for 16-20 wheeled waste bins)

Tank capacity: 24,000 litres (equivalent to 24 tonnes food waste)

The science

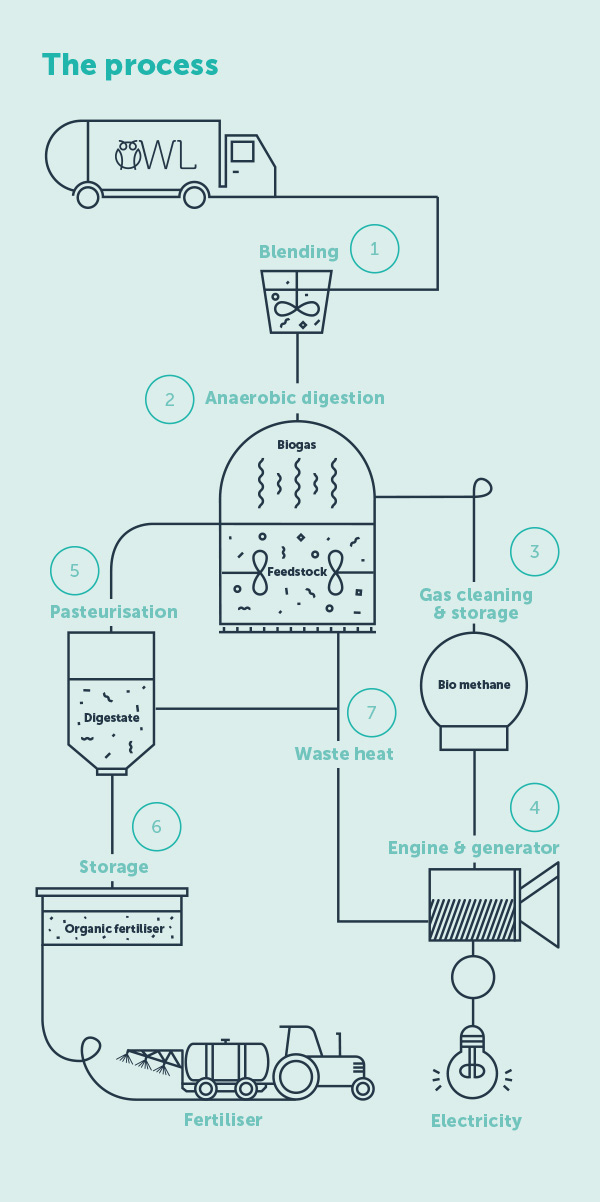

Anaerobic digestion is a collection of natural, biological processes in which microorganisms break down organic material (feedstock) – in the absence of oxygen into energy in the form of biogas.

The biogas is then processed and upgraded into a natural gas equivalent product, bio-methane.

Biomenthane can be used for heating or fed to a conventional gas engine to generate electricity. The waste heat from the engine is recycled into a pasteuriser which heats the spent food stock (digestate) to remove any pathogens. The mixture is then a valuable, high nutrient organic fertiliser. Waste heat is also used to warm up the feedstock to enhance and speed up the anaerobic digestion process.

1

Food waste delivery is blended with all the other organic wastes into feedstock.2

The feedstock is fed to micro-organisms (in the absence of oxygen) which breakdown organic material into biogas. The process takes from 3-4 weeks.3

The biogas is processed into a natural-gas equivalent fuel, bio methane.4

The bio methane is fed to a conventional engine and converted into electricity.5

The spent feedstock, digestate, is pasteurised to eliminate any pathogens.6

The pasteurised materials become a nutrient-rich, organic fertiliser, valuable in agriculture and soil conditioning.7

The waste heat from the engine is recycled to supply the heat for pasteurisation and to warm the feedstock, increasing the effectiveness of the anaerobic digestion process.

Benefits to you

Being a part of the OWL solution will make an important contribution to your company’s green certificate efforts. OWL provides customers a report each month detailing the environmental savings generated by their food waste recycling. See a sample of this report here. This information is useful is demonstrating compliance with various green certification programmes. If your organisation is not already participating in a green certification initiative, please see this list of relevant programmes that will give credit to recycling efforts:

Carbon Trust Standard for Carbon

Carbon Trust Standard for Waste

Eco management and Audit Scheme (EMAS)

EU Ecolabel

Green Key

Green Mark

Green Globe

Green Seal

Green Tourism Business Scheme

Hospitality & Food Service Agreement (HaFS)

ISO 1400/14001

Planet Mark

Sustainable Tourism Eco Certification Programme (STEP)

Benefits to the planet

Energy benefit

Anaerobic digestion reduces our use of highly polluting fossil fuels. Furthermore, unlike intermittent renewable energy sources such as wind and solar, energy produced by anaerobic digestion is constant and therefore more valuable.

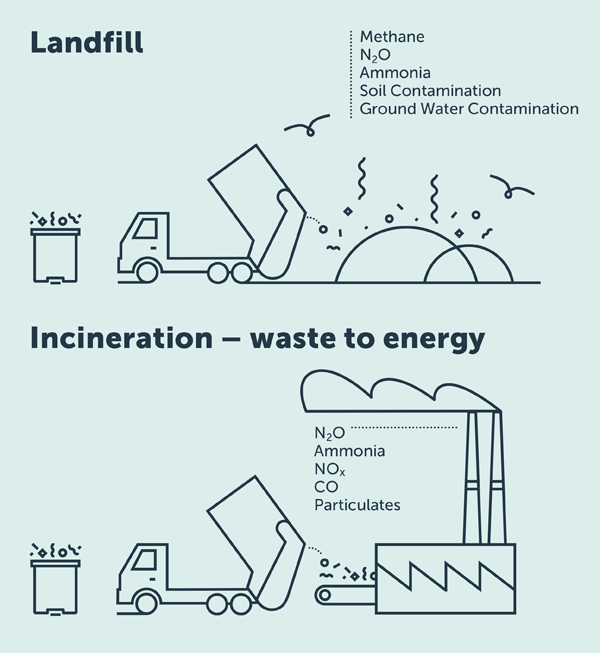

Waste disposal benefit

Anaerobic digestion replaces disposal of waste to landfill sites. Over 80% of non-recycled food waste is currently sent to landfill, which according to a research survey by WRAP (Waste & Resources Action Programme), is 27 times more harmful to the environment compared to anaerobic digestion. Similarly, the small amount of food waste sent for incineration, even using waste-to-energy technology, is 7.5 times more harmful to the environment than anaerobic digestion.

Agricultural Benefit

Anaerobic digestion produces nutrient-rich, organic fertiliser – a less expensive alternative to imported, chemical-based fertiliser.

Transportation Benefit

Adopting the OWL solution decreases the frequency of food waste pick-ups by over 80% – reducing vehicle congestion, emissions and carbon footprint.

What are the utility and space requirements to install OWL's unit?

All that we require is a standard 440v 32 amp electrical connection. Our vacuum storage unit, called the BioWhale, does not require a connection to clean water or waste water services. No permits are required for installation. The BioWhale is built into a standard steel container with a stainless steel waste hopper. There is no extra space required because the unit can occupy space currently used by your food waste bins. There are 3 sizes depending on the volume of your food waste. Our Compact BioWhale unit is 3m by 2.5m (approximately the same space as 4-6 bins). It is also possible to install the system directly in a location without a steel container. In that instance, the BioWhale will occupy virtually the same foot print as the container. The BioWhale is designed and manufactured in the UK by one of Europe's largest pressure vessel manufacturers, Whale Tankers, and meets all UK certification requirements.

How is the food waste removed from the vacuum storage tank?

OWL's vacuum storage unit, the BioWhale, is equipped with an online monitoring system that tracks fill level. When the tank approaches capacity, it will automatically inform the OWL dispatch centre, which will dispatch a sealed vacuum tanker truck to your site. An OWL driver will empty the unit without any involvement from your staff.

How is the food waste recycled?

All food waste will be recycled into green energy (electricity or gas) and organic fertiliser at one of the UK's 150 food waste AD plants. In the vast majority of cases, the food waste will travel less than 30 miles from your location.

How can my company track the environmental savings achieved?

We will provide you with a monthly management report that will show the amount of food waste collected, energy produced, CO2 savings and organic fertiliser produced. We will work with each client to customise the information to help them meet reporting requirements for their environmental certification programmes.

What material can I put in the hopper?

All unpackaged food waste -- "if it's food it's good to go". Prohibited items include plastic or packaging, cutlery and crockery. While we work with your staff to keep the unit food waste only, the unit has the ability to manage small amounts of non-food waste materials, therefore minor occasional mistakes can be managed.

Will I still need bins?

You will no longer require any food waste bins. Of course, you will still require bins for non-food waste, but they will no longer be contaminated by food waste and, therefore, will not have any odour or attract pests/vermin. This will also make them easier to recycle and cheaper to dispose of. In your food preparation areas you can use a broad array of food waste receptacles. We can advise on the options available and assist you on your selection.

What will it cost me to switch to OWL?

There are no up-fronts costs to switch to OWL. We provide and maintain the BioWhale as part of OWL's service, which includes full removal of your food waste and 100% recycling guaranteed. The price of our service will be lower cost than your current solution for food waste disposal.

Does the storage unit require any ongoing service?

OWL provides all servicing, maintenance and repairs as part of your contract. OWL will perform full servicing of the unit twice annually. In the unlikely event of a problem, we have a national service network with 14 locations across the UK, providing radio dispatched service vehicles. Each BioWhale unit's performance is continually monitored online. Any problems will be automatically reported and quickly resolved. In addition, OWL maintains a 24/7 service hotline.

If the unit breaks, what is the likelihood of odour or spillage?

The system is fully vacuum sealed. Even if there is a breakdown or a general power failure, the vacuum is maintained for approximately 2-3 days. Therefore, the odour and the material are contained and will not leak into the environment. Once power is restored, the system automatically restarts itself. In the event of a long term power failure (in excess of 2-3 days) we will dispatch a sealed vacuum tanker to empty the unit.